Hygiene Drainage

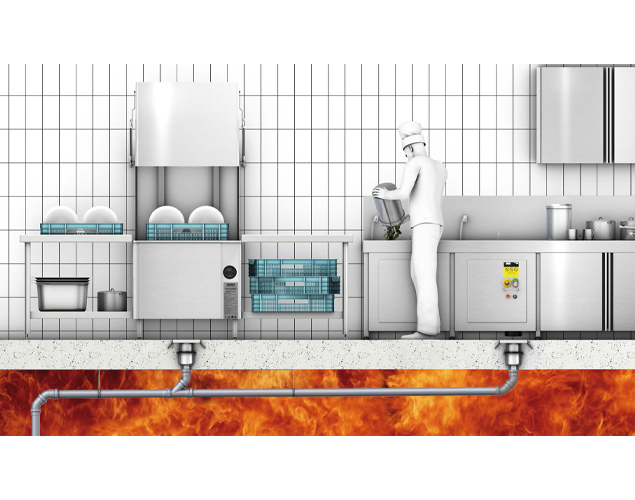

The core components that can contribute to maintaining hygiene in a commercial kitchen include:

- The equipment

- The people

- Ventilation

- The drainage system

With regards to these, ACO has designed a futuristic kitchen drainage system on the philosophy of ‘Hygiene First’ that are in line with the health and safety aspects of any commercial kitchen. The first and only company to receive the 14159-1 Hygiene requirements for the Design of Meat and Poultry Processing Equipment Certification for its products from NSF International, and the EN 1672, EN ISO 14159, and EHEDG documents no. 8, 13, and 44 for their drainage products, this product solution includes various components including:

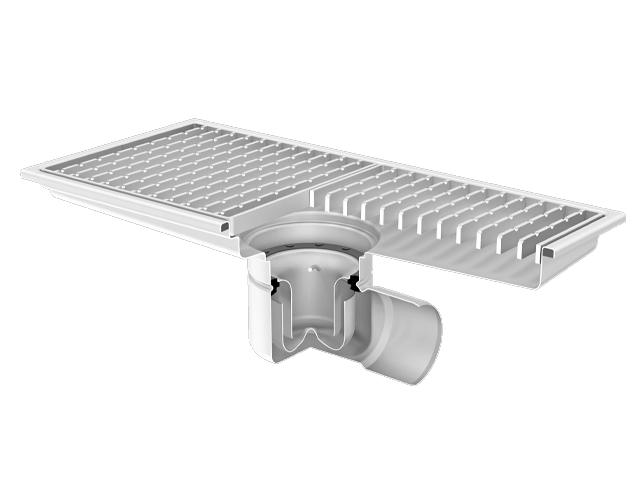

- Gullies

- Box channels

- Modular box channels

- Modular slot channels

- Pipes

- And associated fittings and accessories

Several details like rounded channels make these components easy to maintain, inspect, and use in the long run. Some of these details include:

- Hygienic slip resistant gratings

- Hygienic joints

- Deep body contours that eliminate crevices that harbour bacteria and dirt

- Edge fill-in that stabilizes transmission between the gully and the surrounding floor area

- Foul air trap without overlap joints

- Foul air trap with smooth, rounded internal corners

- The option of a fixed height solution or telescopic solution

- V-shaped bottom to create fully drainable units

- Fully pickled and passivated parts

Ideal for drainage, grease and organic waste management, the cost effectiveness, ease of installation, and ease of maintenance, make these lucrative investments in the long run.